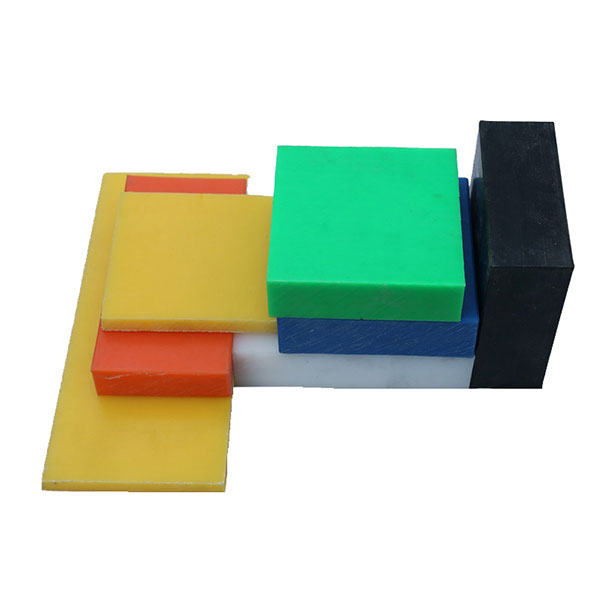

Bridge support skateboard / wear plate features:

The bridge support skateboard/wear plate is an ultra-high molecular weight polyethylene plate embedded in the plate basin support. Due to the low friction coefficient of the ultra-high molecular weight polyethylene plate, the beam end can be free on the surface of the ultra high molecular weight polyethylene plate. Sliding, horizontal displacement is not limited, especially suitable for medium and small loads, large displacement bridges;

Bridge bearing wear plate advantage

The ultra-high molecular weight polyethylene bridge support pad not only has excellent technical performance, but also has the characteristics of simple structure, low price, no need for maintenance, easy replacement, buffer isolation and low building height. Therefore, it is popular in the bridge industry and is widely used.

Installation of bridge supports

1)Fixed: The fixed bearing is not movable and provides horizontal force in all directions.

1-top steel plate; 2-stainless steel plate; 3- UHMWPE sheet ; 4- convex middle plate; 5-sleeve; 6-anchor bolt; 7-rubber sealing ring; 8-base steel plate.

2)Guide slide: The guide bearing can move in one direction and can provide a horizontal force perpendicular to the movable direction.

1-top steel plate; 2- stainless steel plate; 3-UHMWPE sheet ; 4- convex middle plate; 5-guide bar; 6-sleeve; 7-anchor bolt; 8-base steel plate.

3) Free-sliding: Free sliding bearings can move in all directions but cannot provide horizontal forces.

1-top steel plate; 2-stainless steel plate; 3-PTFE or (UHMWPE); 4-convex middle steel; 5-sleeve; 6-anchor bar; 7-base steel plate.

you can contact us in the following ways.

-

Material of Ground Protection Mats: High Density Polyethylene (HDPE) or Ultra High Molecular Weight Polyethylene (UHMWPE) is used, making the product very strong, chemical and weather resistant, and able to withstand the rigors of industrial use. UV inhibitors are added to ensure that the product can be used indoors and outdoors without the risk of fading or weathering. It has a certain degree of rigidity and elasticity, and can withstand heavy vehicles without cracking or breaking.

-

Joseph, an American client , in order to carry out construction on wet grass and protect the ground, initially considered plywood, but after careful consideration, he chose HDPE Ground protection MAT. Why use expensive mats instead of affordable plywood? Because it’s a better long-term investment! Plywood has a limited life space, with a porous surface that soaks up spilled chemicals, water and oils. It can’t be cleaned thoroughly, and doesn’t come with a standardized load b...

-

Japanese customers James do engineering construction recently accepted a project but a few days before the heavy rain led to a site road wet muddy resulting in decreased productivity custome

-

HDPE ground protection mat Light weight, convenient to improve work efficiency in the harsh conditions of the road